Application

Two Ways To Repair Roads & Pavements

Other Application Methods Can Be Used For Large Jobs.

Pothole Application Instructions & Tips

Products Intended For Pothole Repairs: 4Seasons® Pourable Fillers: Coarse, Fine or R4.

Determine size of batch needed: Use the dimension of the pothole to estimate its volume in cu in. (LxWxD). Example 12″ x 12″ x 1″ = 144 cu. in. A full kit yields 4 gallons or 900 cu in. Lesser amounts may be portioned out and mixed in disposable pail for smaller repair needs. Use direct ratios: i.e. 50% liquid to 50% aggregate. This ratio will yield 2 gallons or 450 cu in of filler product.

Prepare Pothole: Begin by removing sand and debris and ALL LOOSE PAVEMENT from area of repair with shovel, leaf blower, or power washer. Wash any trace of calcium chloride, and other deicers, visible grease and oil from surface. Dry area with leaf blower to ensure all water is removed from surface and area is completely dry. If pothole bottom is sand or gravel, cement pavers or larger pavement pieces can be placed at the bottom to give a solid foundation for the repair.

Prime the Pothole: Prime the entire repair area with ecoBOND primer and let it dry to tack.

Mix the Filler: Shake contents of (A) Liquid bladder before pouring into empty mixing pail. Shake (B) Aggregate bag before stirring into liquid in the pail. Use provided stir stick to completely blend into thick slurry. Once product is mixed it must be used; work time is approximately 5 minutes. (Use a smaller disposable pail if partial mixing is required. Discard pail upon use. Re-cap unused liquid and close aggregate bag for future use. Store as directed.)

Fill the Pothole: Pour the filler mix into prepared pothole, filling level to surrounding surface. Product self -levels. Stir Stick may be used to assist material flow and complete contact with edges. If more product is needed to complete the repair, repeat application. 4Seasons® will adhere to itself while wet.

Appearance: This product is asphalt black. Upon full cure (up to 24 hrs.), repairs may be seal coated or painted with durable cement coating to match surrounding surface.

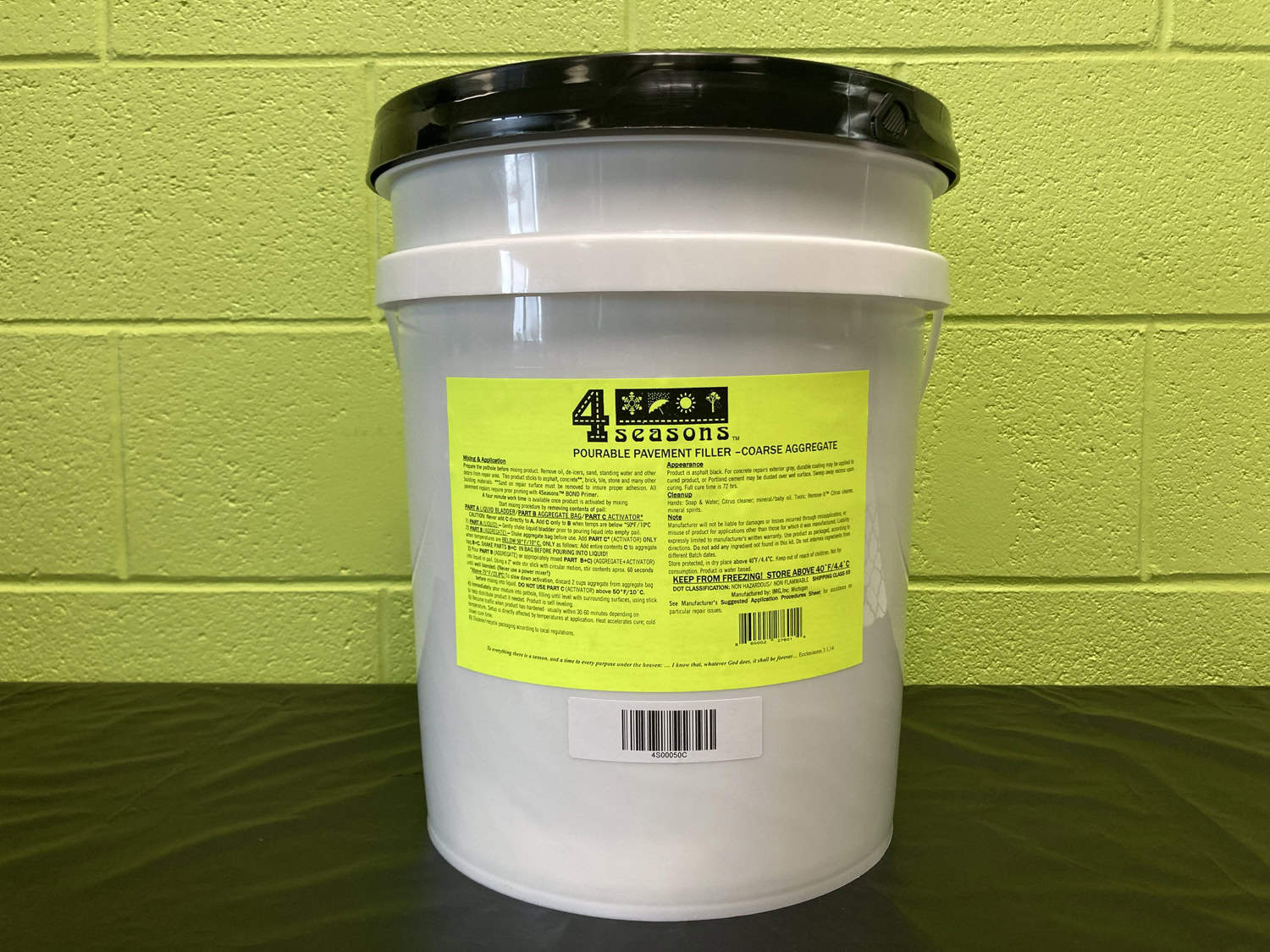

Contents: 5 Gallon Mixing bucket contains 3 components.

(A) Liquid bladder – shake before use.

(B) Aggregate bag – shake before use.

(C) Catalyst zipbag – Add to part B aggregate bag and shake to mix well. Use only for concrete potholes when temperatures are below 50˚F/10˚C to assist cure time. NOTE: Part C is not included/used with R4 Formula.

(A) + (B) = 4Seasons® Filler – Temps ABOVE 50°F/10°C

(A) + (B + C) = 4Seasons® Filler – Temps BELOW 50°F/10°C to accelerate setup time in cold weather.

(A) + (B – 1 cup) = 4Seasons® Filler – Temps ABOVE 75°F/23.89°C to slow down setup in hot weather.

Linear Crack Application Instructions & Tips

Products Intended For Linear Crack Repairs: 4Seasons® Pourable Fillers: Coarse, Fine.

Determine Amount of Filler Needed: Use the dimension of the crack to estimate its volume in cu in. (D x W x L). Example 1″ x 1/2″ x 360″ = 180 cu. in. A full kit yields 4 gallons or 900 cu in. Lesser amounts may be portioned out and mixed in disposable pail for smaller repair needs. Use direct ratios: i.e. 50% liquid to 50% aggregate. This ratio will yield 2 gallons or 450 cu in of filler product.

Prepare Cracks: Begin by removing sand and debris and ALL LOOSE PAVEMENT from area of repair with shovel, leaf blower, or power washer. Wash any trace of calcium chloride, and other deicers, visible grease and oil from surface. Dry area with leaf blower to ensure all water is removed from surface and area is completely dry. If the crack is deeper than 1”, use 4Seasons® part B aggregate to pour down into the crack to provide a base, leaving approx. ½” for Filler product to seal crack.

Prime the Crack: Not needed.

Mix the Filler: Shake contents of (A) Liquid bladder before pouring into empty mixing pail. Shake (B) Aggregate bag before stirring into liquid in the pail. Use provided stir stick to completely blend into thick slurry. Once product is mixed it must be used; work time is approximately 5 minutes. (Use a smaller disposable pail if partial mixing is required. Discard pail upon use. Re-cap unused liquid and close aggregate bag for future use. Store as directed.)

Fill the Linear Crack: Immediately pour the mix into linear crack, filling just over the top. If more product is needed, repeat mixing process and apply to fill entire linear crack.

Appearance: This product is asphalt black. Upon full cure (up to 24 hrs.), repairs may be seal coated or painted with durable cement coating to match surrounding surface.

Contents: 5 Gallon Mixing bucket contains 3 components.

(A) Liquid bladder – shake before use.

(B) Aggregate bag – shake before use.

(C) Catalyst zipbag – Not to be used for linear cracks.

(A) + (B) = 4Seasons® Filler – Temps ABOVE or BELOW 50°F/10°C

(A) + (B – 1 cup) = 4Seasons® Filler – Temps ABOVE 75°F/23.89°C to slow down setup in hot weather.

Alligator Crack Application Instructions & Tips

Products Intended For Alligator Crack Repairs: 4Seasons® Pourable Fillers: Coarse, Fine.

Alligator cracks are a series of cracks in close proximity over a given area like a spider’s web. This patching method can be used in parking areas (not high-traffic areas) where the stone in the blacktop is present but the emulsion has pulled away and is about 1/8th” – 1/4″ below the stone. This patch will be thin, but long lasting when applied properly and can extend the life of the pavement surface and postpone a major repaving job.

Determine size of batch needed: Use the dimension of the crack to estimate its volume in cu in. (D x W x L). Example 1″ x 1/2″ x 360″ = 180 cu. A full kit yields 4 gallons or 900 cu in. Lesser amounts may be portioned out and mixed in disposable pail for smaller repair needs. Use direct ratios: i.e. 50% liquid to 50% aggregate. This ratio will yield 2 gallons or 450 cu in of filler product.

Prepare alligator cracks: Begin by removing sand and debris and ALL LOOSE PAVEMENT from area of repair with shovel, leaf blower, or power washer. Wash any trace of calcium chloride, and other deicers, visible grease and oil from surface. Dry area with leaf blower to ensure all water is removed from surface and area is completely dry.

Prime the alligator crack: Prime the entire repair area with ecoBOND primer and let it dry to tack.

Mix the Filler: Shake contents of (A) Liquid bladder before pouring into empty mixing pail. Shake (B) Aggregate bag before stirring into liquid in the pail. Use provided stir stick to completely blend into thick slurry. Once product is mixed it must be used; work time is approximately 5 minutes. (Use a smaller disposable pail if partial mixing is required. Discard pail upon use. Re-cap unused liquid and close aggregate bag for future use. Store as directed.)

Fill the alligator crack: Pour product over pre-primed repair surface, using trowel or squeegee to cover entire area ensuring that the cracks are filled. Leave at least a ¼” depth of product over pavement surface to seal pavement repair. Lesser depths may wear away, but product will remain in the cracks and voids of the repair. If more product is needed to complete the repair, repeat application. 4Seasons® will adhere to itself while wet.

Appearance: This product is asphalt black. Upon full cure (up to 24 hrs.), repairs may be seal coated or painted with durable cement coating to match surrounding surface.

Contents: 5 Gallon Mixing bucket contains 3 components.

(A) Liquid bladder – shake before use.

(B) Aggregate bag – shake before use.

(C) Catalyst zipbag – Not used for alligator cracks.

(A) + (B) = 4Seasons® Filler – Temps ABOVE 50°F/10°C

(A) + (B – 1 cup) = 4Seasons® Filler – Temps ABOVE 75°F/23.89°C to slow down setup in hot weather.

Concrete Application Instructions & Tips

Products Intended For Concrete Repairs: 4Seasons Pourable Fillers: Coarse, Fine.

Concrete repairs may include potholes, cracks and spalded areas. ecoBOND primer must be used for all concrete repairs prior to applying filler products. This product is asphalt black. After full cure (24 hours of dry weather), repairs can be painted with a durable cement coating to blend with surrounding surface.

Determine size of batch needed: Use the dimension of the damaged area to estimate its volume in cu in. (LxWxD). Example 12″ x 12″ x 1″ = 144 cu. in. A full kit yields 4 gallons or 900 cu in. Lesser amounts may be portioned out and mixed in disposable pail for smaller repair needs. Use direct ratios: i.e. 50% liquid to 50% aggregate. This ratio will yield 2 gallons or 450 cu in of filler product.

Prepare concrete: Begin by removing sand and debris and ALL LOOSE PAVEMENT from area of repair with shovel, leaf blower, or power washer. Wash any trace of calcium chloride, and other deicers, visible grease and oil from surface. Dry area with leaf blower to ensure all water is removed from surface and area is completely dry.

Prime Concrete: Prime the entire repair area with ecoBOND primer and let it dry to tack.

Mix the Filler: Shake contents of (A) Liquid bladder before pouring into empty mixing pail. Shake (B) Aggregate bag or (B+C with temperatures below 50°F/10°C) before stirring into liquid in the pail. Use provided stir stick to completely blend into thick slurry. Once product is mixed it must be used; work time is approximately 5 minutes. (Use a smaller disposable pail if partial mixing is required. Discard pail upon use. Re-cap unused liquid and close aggregate bag for future use. Store as directed.)

Fill the concrete void: Pour product into pre-primed hole or crack using trowel or squeegee to cover entire area ensuring adhesion, filling level to surrounding pavement. If more product is needed to complete the repair, repeat application. 4Seasons® will adhere to itself while wet.

Appearance: This product is asphalt black. Upon full cure (up to 24 hrs.), repairs may be seal coated or painted with durable cement coating to match surrounding surface.

Contents: 5 Gallon Mixing bucket contains 3 components.

(A) Liquid bladder – shake before use.

(B) Aggregate bag – shake before use.

(C) Catalyst zipbag – Add to part B aggregate bag and shake to mix well. Use only when temperatures are below 50˚F to assist cure time.

(A) + (B) = 4Seasons® Filler – Temps ABOVE 50°F/10°C

(A) + (B + C) = 4Seasons® Filler – Temps BELOW 50°F/10°C to accelerate setup time in cold weather.

(A) + (B – 1 cup) = 4Seasons® Filler – Temps ABOVE 75°F/23.89°C to slow down setup in hot weather.

Non-Level Surface Application Instructions & Tips

Products Intended For Non-Level Repairs: 4Seasons® Pourable Fillers: Coarse, Fine or R4.

Non-Level surface repairs: Trip hazards such as sidewalks that lift; or meeting of differing pavement heights (1/2″-3″ off ) such as doorways that step down, can be corrected with 4Seasons® fillers.

Determine size of batch needed: Use the dimension of the repair area to estimate its volume in cu in. (LxWxD). Example 12″ x 12″ x 1″ = 144 cu. in. A full kit yields 4 gallons or 900 cu in. Lesser amounts may be portioned out and mixed in disposable pail for smaller repair needs. Use direct ratios: i.e. 50% liquid to 50% aggregate. This ratio will yield 2 gallons or 450 cu in of filler product.

Prepare non-level surface: Begin by removing sand and debris and ALL LOOSE PAVEMENT from area of repair with shovel, leaf blower, or power washer. Wash any trace of calcium chloride, and other deicers, visible grease and oil from surface. Dry area with leaf blower to ensure all water is removed from surface and area is completely dry. If repair edge is open, with no adjacent pavement to hold repair material, form boards must be made of wood or similar substance wrapped in plastic to release from 4Seasons® once repair is cured. Place wrapped form boards on edge of repair area and secure with stakes on outside of board. Remove form boards immediately after 4Seasons® begins to set up.

Prime: Prime the entire repair area with ecoBOND primer and let it dry to tack.

Mix the Filler: Shake contents of (A) Liquid bladder before pouring into empty mixing pail. Shake (B) Aggregate bag or (B+C with temperatures below 50°F/10°C) before stirring into liquid in the pail. Use provided stir stick to completely blend into thick slurry. Once product is mixed it must be used; work time is approximately 5 minutes. (Use a smaller disposable pail if partial mixing is required. Discard pail upon use. Re-cap unused liquid and close aggregate bag for future use. Store as directed.)

Fill the non-level surface void: Pour product into pre-primed repair surface, using trowel to cover entire area, working the material into a ramp that levels, ensuring adhesion to surrounding pavement. If more product is needed to complete the repair, repeat application. 4Seasons® will adhere to itself while wet.

Appearance: This product is asphalt black. Upon full cure (up to 24 hrs.), repairs may be seal coated or painted with durable cement coating to match surrounding surface.

Contents: 5 Gallon Mixing bucket contains 3 components.

(A) Liquid bladder – shake before use.

(B) Aggregate bag – shake before use.

(C) Catalyst zipbag – Add to part B aggregate bag and shake to mix well. Use only when temperatures are below 50˚F to assist cure time. NOTE: Part C is not included/used with R4 Formula.

(A) + (B) = 4Seasons® Filler – Temps ABOVE 50°F/10°C

(A) + (B + C) = 4Seasons® Filler – Temps BELOW 50°F/10°C to accelerate setup time in cold weather.

(A) + (B – 1 cup) = 4Seasons® Filler – Temps ABOVE 75°F/23.89°C to slow down setup in hot weather.